POSTED ON. Two Items

August rains and American parties

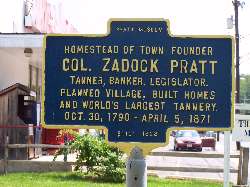

They have not had a great summer in the US this year but the last two weeks in New England have been just fine, and it is hard to think that just a few days ago we were in famous tanning towns such as Tannersville, Hunter and Prattsville in New York State. Indeed last weekend the town of Prattsville celebrated 175 years and seemed to have had a very good time according to the team at the Young Agriculture store, or Youngs Agway as it seems to be called. Youngs is interesting as it somewhere here, or on the strip of land between the store and the river Schoharie that a man called Zadock Pratt started his hemlock bark tannery in 1824. The 175th refers to the fact that he had the town named after himself in 1833, just like any other modest tanner would have done.

Yes, we are in the Catskills in New York and in the second quarter of the 19th century tanners changed this area of America quite dramatically. They built new tanneries and brought in workers and along with them drugs, drink and prostitution. They cut the trees down to get at the bark and burnt the unwanted wood regularly setting fire to huge areas of forest as a consequence. According to the Zadock Pratt Museum web site www.prattmuseum.com foresters have estimated that the tanneries built in Hunter and Prattsville during their twenty year existence each probably used up over 1,500,000 hemlocks.

Taking the hides to the tannin

It was Sir Humphry Davy who in 1803 made the discovery that led the US to start vegetable tanning with Hemlock and soon after it was found easier to ship the hides from New York, along with other hides transhipped from Latin America, to tanneries in the Catskills rather than tanning them in New York. The first tannery was built in 1817 but it was in the 1820s ththe at tannery building accelerated in the Catskills. Zadock Pratt was to build the biggest and by all accounts the best. He built it in 1824 and it closed in 1846. According to local historian Carolyn Bennett whom we met in Tannersville the tanners of the 19th century Catskills remain pretty much a hated breed for the damage they did to the forests and the water courses.

Her view is that Zadock Pratt was by far the best of a bad bunch. He took more care of the forest, built houses for his work force to create a family based community rather than a wild frontier town, and set the community up in farming to replace the employment that would be lost when the tannery closed. This was a predictable date. When he built the tannery he described it as the largest in the world. It had 300 tan vats which from the drawings were mostly outside and processed 60,000 hides a year using 6000 cords of bark and 1500 cords of wood. He employed 300 men. As the hauling of hemlock bark became more difficult it became apparent that a ten mile radius was the furthest out any one tannery could economically reach for bark. They cut trees with a minimum diameter of 12 to 14 inches which had enough bark to make them worthwhile and so it became possible to predict the end of tanning in the town.

Pratt stayed linked to Prattsville having founded a bank and the newspaper and involved in lots of businesses. He also became a partner in a number of other New York State tanneries such as in Windham, Big Hollow, Palenville, Westkill and Samsonville as well as in Aldenville, Pennsylvania. He was also an important US congressman. The museum in Prattsville is his old house.

Running out of trees

So around the 1840s they started to run out of trees to cut for bark and historians tell us that 1846 saw the collapse of the tanning business and the gradual rise of the still famous Catskill summer resort trade, which reached its peak in 1882 when the railroad came to Tannersville. Driving through today winter sports now seem equally important.

When the Catskills closed some tanners just moved on to the Adirondacks, a couple of hours to the north, where it took until about 1880 for them to run out of suitable trees. So if any of you wonder why there is a big shoe industry still headquartered around Boston but the tanneries were all much further out the location of extensive hemlock or oak forests was the reason. After the Adirondacks tanners had worked out how to make extract and generally speaking location became less of an issue. There are only the remains left of one or two Catskill tanneries and they are not very accessible, but in the Adirondacks more can be found. I am bringing back to the University some pieces of leather found on the forest by an old taney which are thought to date back to about 1880. We are hoping to confirm that these pieces are all hemlock tanned.

Mike Redwood

23rd August 2008POSTED ON

Chinese and Cricket

I’m sitting in the Chinese restaurant Hsin Kwans and watching England trying to bowl South Africa out in their final innings of the test match. I’ve spent the week visiting tanneries, shoe and garment factories and have met more alumni than I can count. My picture shows me with Salman Butt who works as R&D Manager at the Siddiq Leather Works. Siddiq is part of the Shafi group and is one of the few tanneries in the world which is ISO14000 certified.

This is Lahore in Pakistan and it is eight years since I have had the chance to visit. It is like being with tanners and shoemakers anywhere in the world as within the first few minutes you are talking about events and people all over the world. If ever there was an industry that is worthy of the global name then it is the leather industry.

Watching the lights go out

One way you know you are in Pakistan is that every now and then the lights go out. In better restaurants like this and the bigger factories they have their own generators. After a moment these click in so you do not miss the South African captain Graeme Smith hitting his next four off Monty Panesar. For small factories and for people at home it is a disaster as you appear to lose many hours every day to power cuts, with no warning or possibility to plan.

In Lahore and Karachi are some fine tanneries that many of us know about not just from studying with the teams that now manage them, but also from seeing their leather in the market place over many years. Pakistan has a lot of good raw material, a number of top tanneries and we are seeing some emerging footwear and garment businesses also coming to the fore. An interesting moment when China is seemingly less interested in the leather industry.

Kasur – a way of life

The most famous tanning centre in Pakistan is without doubt Kasur. On my web site I found I had written many years ago just a couple of lines –

Near Lahore in Pakistan, a 200 year old tanning centre which in 2001 was still trying to resolve effluent problems with the help of UNIDO. Kasur tanners make from the raw and sell quite large amounts to Karachi and Sialkot tanners in wet blue

Things have changed now. There are still 250 tanneries whose history goes through the period of using local babool for tanning for the local market through making the EI material that underpinned so much of British leather making in the first half to three quarters of the 20th century. Since the 1970s they have been mostly chrome tanning, and as well as supplying wet blue to other tanneries in Pakistan they now have some limited finishing capabilities in the town and some of the larger units like HS Ali (also full of alumni) can make some fine leathers.

It is hard to get to grips with this place with its narrow streets and donkey carts everywhere. But every piece of waste is supposedly being removed and used effectively for glue, gelatine, leather-board, tent edges etc and the big primary treatment plant is working well. Taken on face value there is a lot to do to make this right from a health and safety point of view, and to move to secondary treatment at least but it is just like walking into an old S.Croce sull Arno. I have to say when I went to work in S.Croce in the early 1970s the smell was a lot worse than it is in Kasur.

Kasur will have to change and develop quite rapidly to survive, but with its well laid brick roads a deep clean and a little change of mindset those of you who know it should think of design centres, ice cream parlours and Starbucks with WiFi set in the brick buildings along the roads amidst these 250 crowded tanneries.

Well, someone has to dream.

Mike Redwood

2nd August 2008